Provide you with the latest enterprise and industry news.

Product Introduction

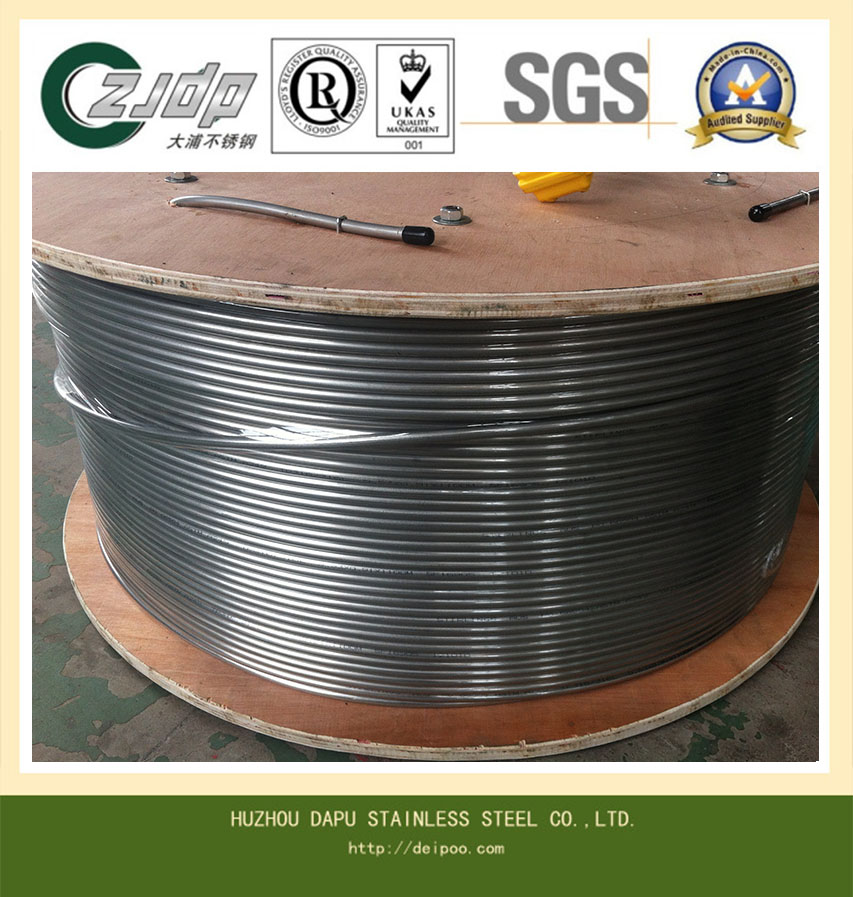

Stainless steel wire is a versatile metal product renowned for its good corrosion resistance, mechanical strength and aesthetic appeal, which makes it an ideal choice for a wide range of industrial and commercial applications. Below is a detailed introduction from surface characteristics, material composition and typical applications.

- Surface Characteristics

The surface finish of stainless steel wire is tailored to meet diverse application requirements, with common types including:

Bright Surface: Obtained through processes like drawing, polishing or annealing, this surface boasts a smooth, glossy appearance with low roughness. It has very good corrosion resistance and is widely used in decorative applications, precision instruments and food processing equipment.

Annealed Surface: After annealing treatment, the wire features a soft, matte finish with uniform color. This surface is suitable for subsequent processing such as bending, weaving and welding, as the annealing process improves the material’s ductility.

Pickled Surface: Formed by pickling to remove oxide scales, this surface is clean and free of impurities. It is commonly applied in industrial fields where corrosion resistance is a basic requirement.

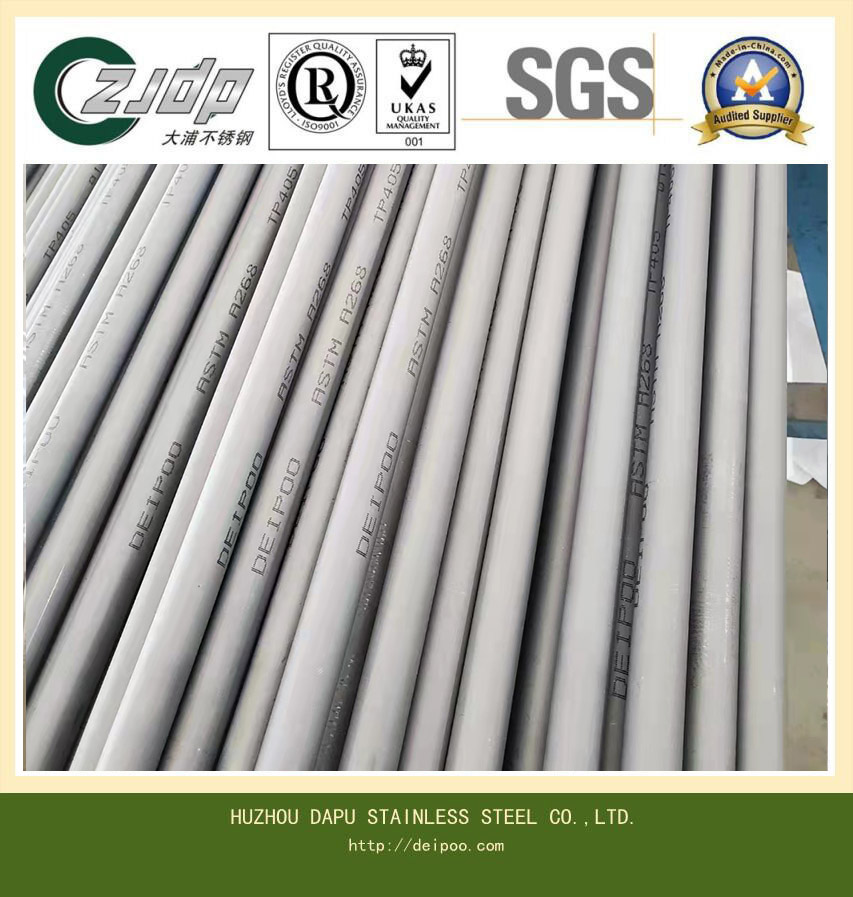

- Material Composition & Grades

Stainless steel wire is primarily alloyed with iron, chromium (minimum 10.5%) and nickel, with other trace elements (e.g., molybdenum, titanium, manganese) added to enhance performance. The widely commonly used grades are:

Austenitic Stainless Steel Wires (e.g., 304, 316): The widely applied category. 304 stainless steel wire contains 18% chromium and 8% nickel, offering good corrosion resistance and formability for general-purpose uses. 316 stainless steel wire adds molybdenum, which significantly improves its resistance to chloride corrosion, making it suitable for marine environments and chemical industries.

Ferritic Stainless Steel Wires (e.g., 430): With a chromium content of 16%–18% and no nickel, this grade is cost-effective and has good oxidation resistance. It is commonly used in automotive trim and household appliances.

Martensitic Stainless Steel Wires (e.g., 410, 420): Characterized by high hardness and wear resistance after heat treatment, these grades are ideal for manufacturing cutting tools, springs and fasteners.

- Typical Applications

Thanks to its outstanding performance, stainless steel wire is used across multiple industries:

Construction & Decoration: Woven into wire mesh for building facades, fences and stair railings; used as binding wire for reinforcing concrete structures.

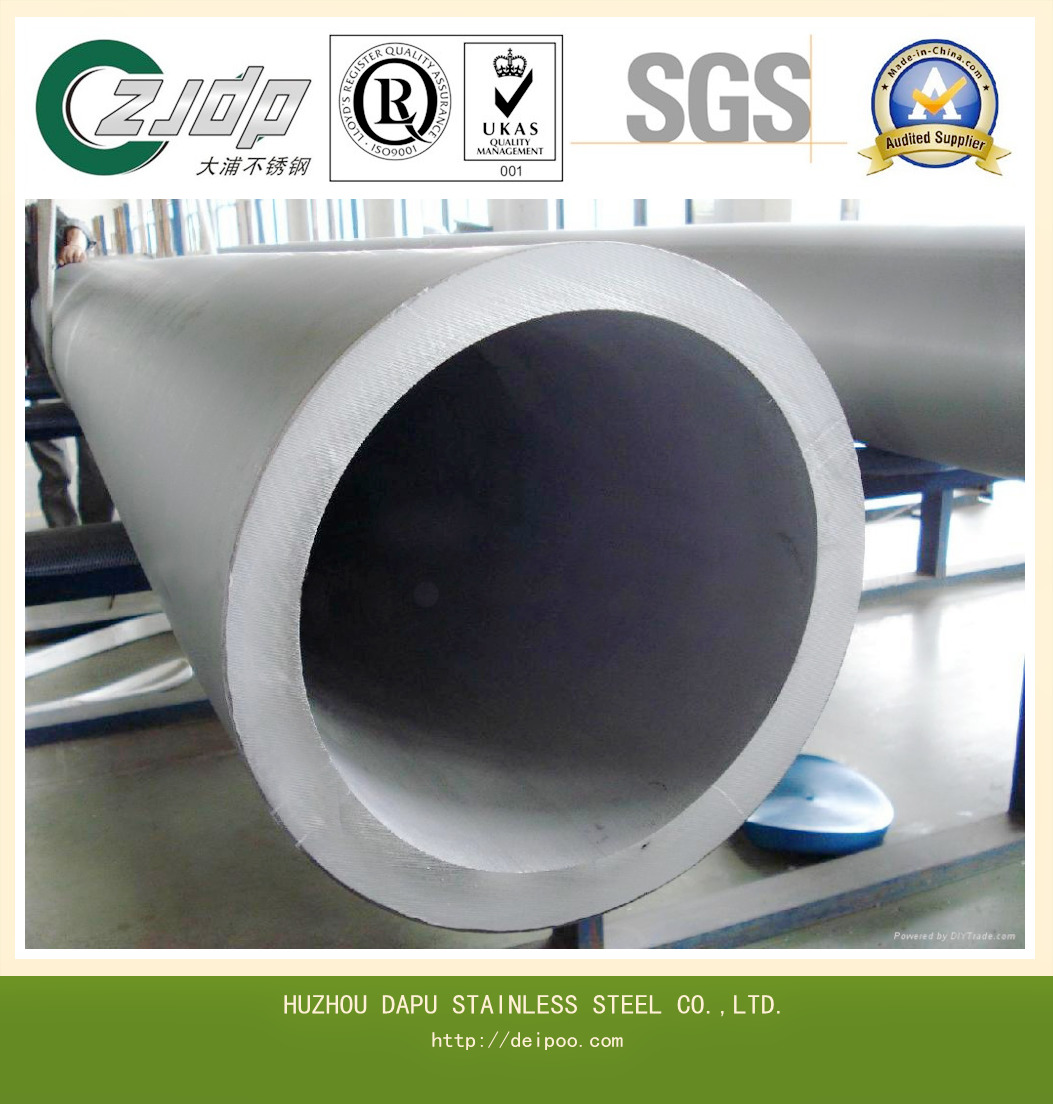

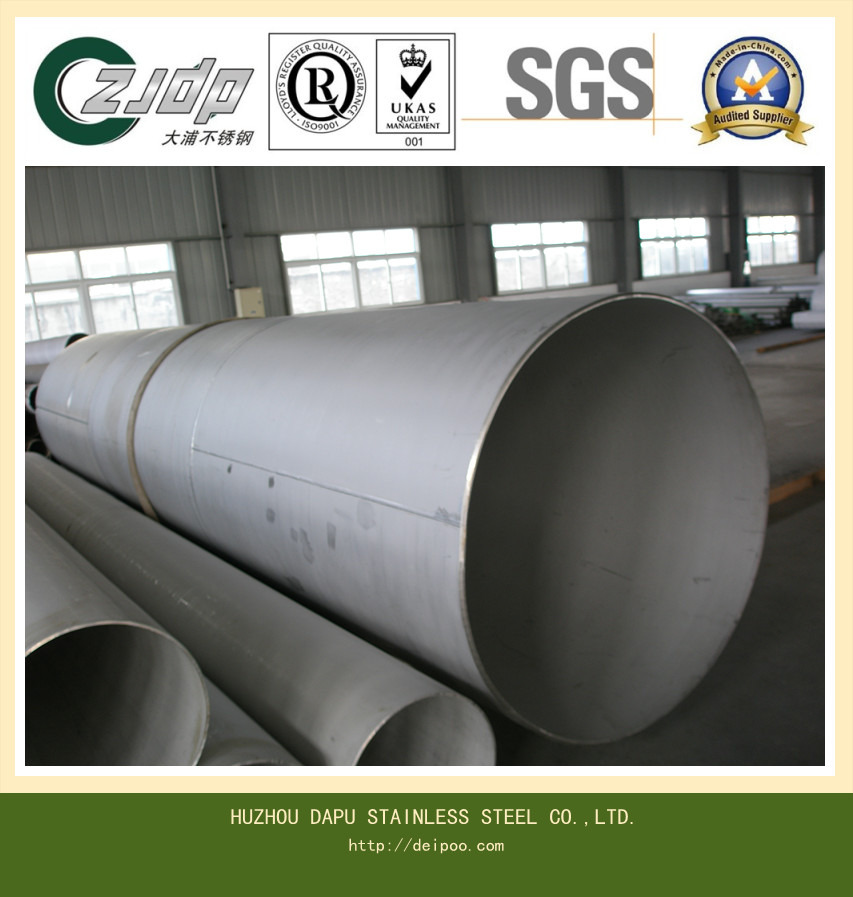

Industrial Manufacturing: Processed into springs, fasteners (screws, nails), wire ropes and filter elements; applied in chemical equipment, heat exchangers and pipeline systems.

Household & Daily Use: Made into kitchen utensils (e.g., wire racks, whisks), cleaning brushes and small hardware accessories; used in pet cages and gardening supports.

Medical & Food Industries: 316L stainless steel wire (low-carbon variant) is used to manufacture surgical instruments, orthopedic implants and food processing machinery components, as it meets strict hygiene and biocompatibility standards.

English

English русский

русский

r``@kt_5-2.jpg)

r``@kt_5.jpg)

r``@kt_5-1.jpg)