Provide you with the latest enterprise and industry news.

Guarantee High Quality With Our Expertise

-

Mr John: +86-13857275119 +86-0572-2566118

Mrs Loel: +86-13616725419 +86-0572-2566115

SUBSIDIARY:Huzhou Dapu Advanced Material Technology Co., Ltd.

product

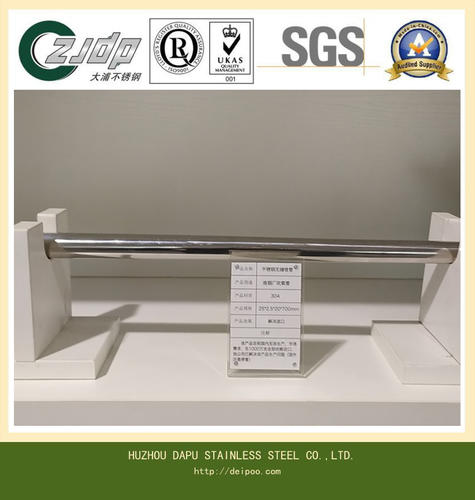

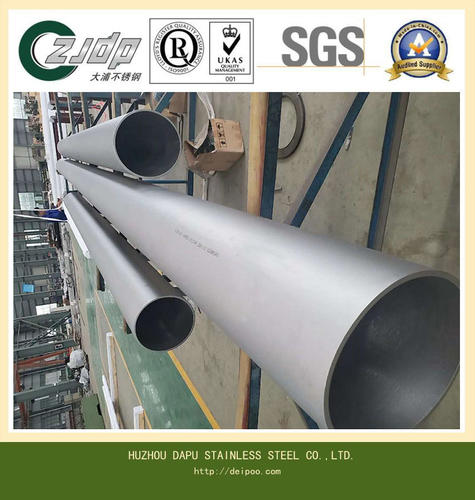

Stainless Steel Heat Exchanger Tubes Manufacturers

Huzhou Dapu Stainless Steel Co., LTD.

About Us

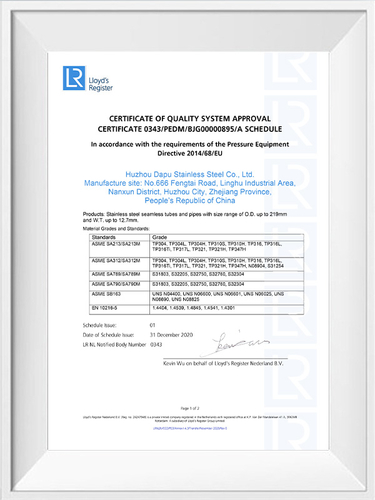

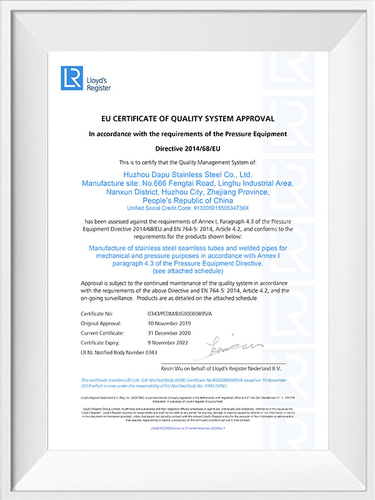

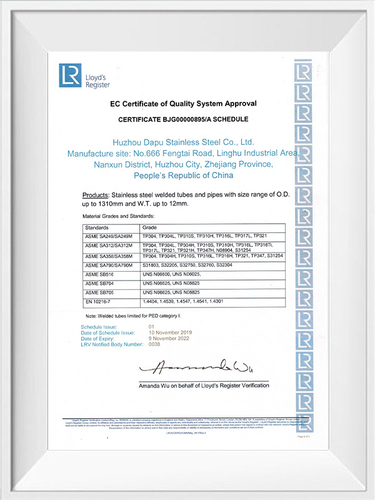

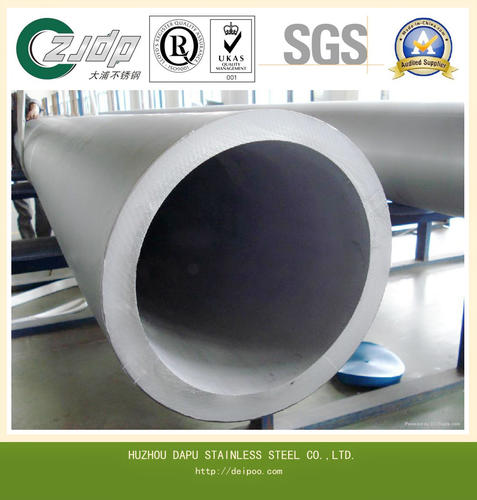

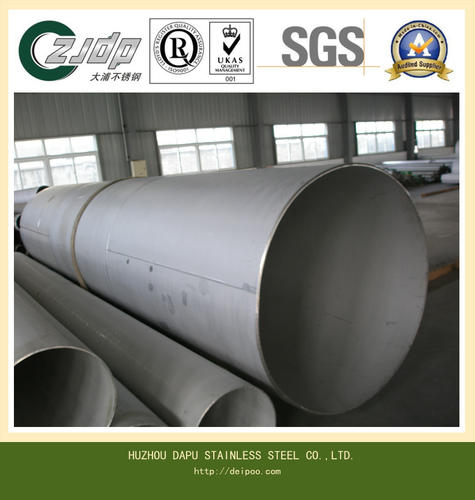

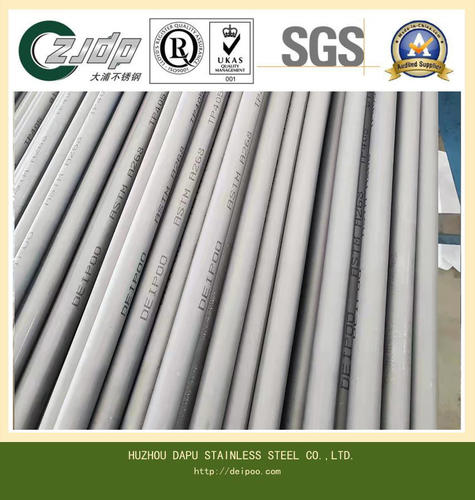

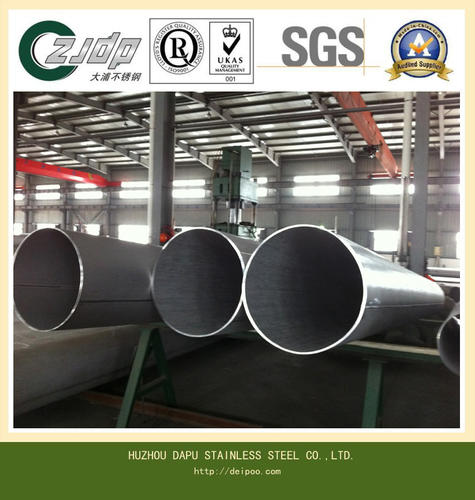

Huzhou Dapu Stainless Steel Co., LTD. is China Stainless Steel Heat Exchanger Tubes Manufacturers and Stainless Steel Heat Exchanger Tubes suppliers.As a strong corporate enterprise, the company has stainless steel (nickel-based alloy) welded pipe manufacture, stainless steel (nickel-based alloy )seamless pipe manufacture and stainless steel machine manufacture, professional production and operation of wholesale Stainless Steel Heat Exchanger Tubes.focuses on more comprehensive and thoughtful to meet the requirements of the customer. Company has obtained PED, ISO and Manufacture License of Special Equipment certificates.

The company annual production capacity is 15000 tons of stainless steel welded pipe, 8000 Tons of seamless stainless steel and 5000 tons of Nickel-base alloy pipes. The company has a professional testing center,with advanced testing equipment at home and abroad: eddy current flaw detector, ultrasonic flaw detector, direct-reading spectrometer, X-raydetector, pressure unit, universal pressure test apparatus, and crystal physics and chemistry, equipment. our custom Stainless Steel Heat Exchanger Tubes in strict line with ASTM(ASME), EN, DIN, JIS, GB and other international standard.

the latest news

-

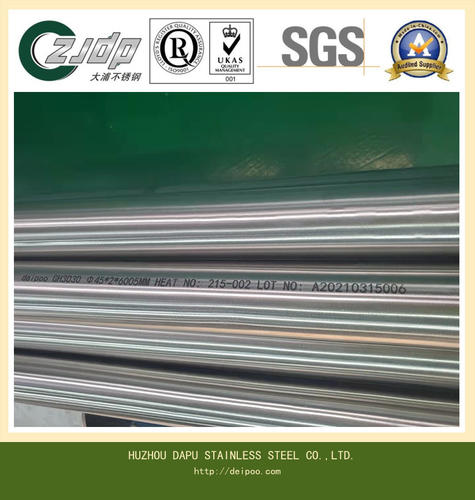

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本-副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

HUZHOU DAPU ADVANCED MATERIAL TECHNOLOGY CO.,LTD BE ESTABLISHED

Affected by the epidemic around the world, Positive to meet the challenge.DAPU team make a quick decision to establish a new company named HUZHOU DAPU ADVANCED MATERIAL TECHNOLOGY CO.,LTD in 2020...

Honor Certificate

What are Stainless Steel Heat Exchanger Tubes

Stainless steel heat exchanger tubes are tubes made from stainless steel that are used in a heat exchanger. A heat exchanger is a device that transfers heat from one fluid to another, or from a solid surface to a fluid. Stainless steel is a common material for heat exchanger tubes because it has good corrosion resistance and high temperature strength. Stainless steel heat exchanger tubes can be used in a variety of applications, such as chemical processing, oil and gas production, and HVAC systems. They are available in a range of sizes, grades, and finishes to suit different applications.

Uses of Stainless Steel Heat Exchanger Tubes

Stainless steel heat exchanger tubes are used in a variety of industrial and commercial applications. Some of the most common uses include:

1.Power Generation: Stainless steel heat exchanger tubes are used in power plants to transfer heat from steam to water.

2.Chemical Processing: Stainless steel heat exchanger tubes are used in chemical processing to transfer heat between different chemicals.

3.Petroleum and Gas Production: Stainless steel heat exchanger tubes are used in the oil and gas industry to transfer heat from hot fluids, such as the steam used in enhanced oil recovery, to production fluids.

4.HVAC Systems: Stainless steel heat exchanger tubes are used in heating, ventilation, and air conditioning systems to transfer heat between the air and a fluid, such as water or refrigerant.

5.Food and Beverage Processing: Stainless steel heat exchanger tubes are used in food and beverage processing to transfer heat between different fluids and to keep food products at a safe temperature.

6.Pharmaceuticals: Stainless steel heat exchanger tubes are used in the pharmaceutical industry to transfer heat between different fluids and maintain a safe temperature during the production process.

7.Marine: Heat exchanger tubes are used in marine industry like ships and boats to transfer heat between the seawater used to cool engines and the fresh water used in various onboard systems.

Stainless Steel Heat Exchanger Tubes have wide range of usage due to its corrosion resistance, durability and reliability.

Advantages of Stainless Steel Heat Exchanger Tubes

Stainless steel heat exchanger tubes have several advantages over other types of heat exchanger tubes. Some of the main advantages include:

1.Corrosion resistance: Stainless steel is highly resistant to corrosion, which means that it can withstand exposure to a wide range of chemicals and environments without rusting or corroding. This makes stainless steel heat exchanger tubes well suited for use in harsh or demanding environments, such as chemical processing plants or offshore oil and gas platforms.

2.High Temperature Strength: Stainless steel can withstand high temperatures, making it suitable for use in heat exchangers that operate at high temperatures.

3.Durability: Stainless steel is a strong and durable material that can withstand a lot of wear and tear. This makes stainless steel heat exchanger tubes well suited for use in applications that involve high pressures, high velocities, or high temperatures.

4.Low maintenance: Stainless steel heat exchanger tubes require minimal maintenance, resulting in a low total cost of ownership.

5.Cleanability : Stainless steel surface are highly polished finish, which makes it easy to clean and maintain hygienic condition, which important in food and Pharmaceutical industries.

6.Recyclable: Stainless steel is a recyclable material, which makes it an environmentally friendly option.

7.Easy to fabricate: Stainless steel is easy to fabricate, which allows manufacturers to produce heat exchanger tubes in a wide range of sizes, shapes, and configurations to meet specific application requirements.

8.Long lasting : Stainless steel heat exchanger tubes have a long life expectancy and do not need to be replaced as frequently as other types of heat exchanger tubes, which can save money over time.

Contact us now

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本-副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

English

English русский

русский

r``@kt_5-2.jpg?imageView2/2/w/500/h/500/format/jp2/q/75)

r``@kt_5.jpg?imageView2/2/w/500/h/500/format/jp2/q/75)

r``@kt_5-1.jpg?imageView2/2/w/500/h/500/format/jp2/q/75)