Provide you with the latest enterprise and industry news.

Guarantee High Quality With Our Expertise

-

Mr John: +86-13857275119 +86-0572-2566118

Mrs Loel: +86-13616725419 +86-0572-2566115

SUBSIDIARY:Huzhou Dapu Advanced Material Technology Co., Ltd.

Huzhou Dapu Stainless Steel Co., LTD.

About Us

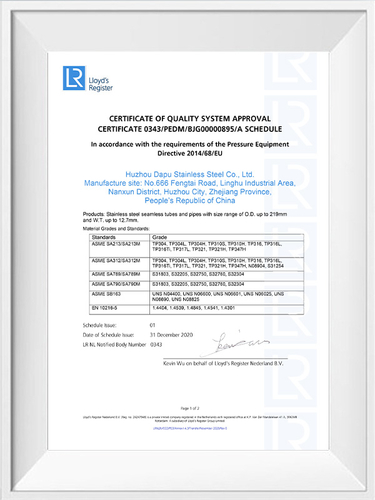

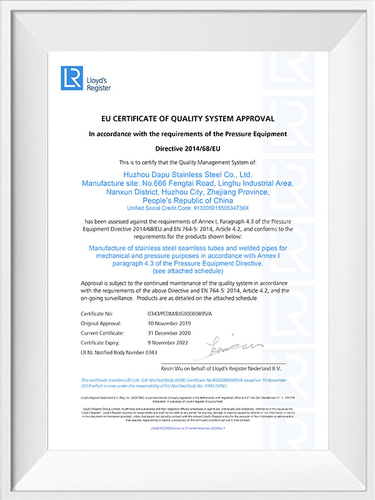

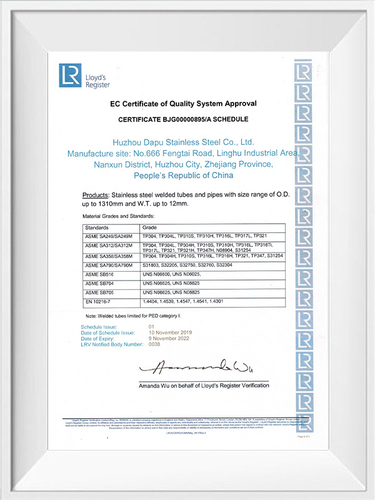

Huzhou Dapu Stainless Steel Co., LTD. is China Martensitic Stainless Steel Factory and OEM/ODM Martensitic Stainless Steel Company.As a strong corporate enterprise, the company has stainless steel (nickel-based alloy) welded pipe manufacture, stainless steel (nickel-based alloy )seamless pipe manufacture and stainless steel machine manufacture, professional production and operation of wholesale Martensitic Stainless Steel.focuses on more comprehensive and thoughtful to meet the requirements of the customer. Company has obtained PED, ISO and Manufacture License of Special Equipment certificates.

The company annual production capacity is 15000 tons of stainless steel welded pipe, 8000 Tons of seamless stainless steel and 5000 tons of Nickel-base alloy pipes. The company has a professional testing center,with advanced testing equipment at home and abroad: eddy current flaw detector, ultrasonic flaw detector, direct-reading spectrometer, X-raydetector, pressure unit, universal pressure test apparatus, and crystal physics and chemistry, equipment. our Martensitic Stainless Steel in strict line with ASTM(ASME), EN, DIN, JIS, GB and other international standard.

the latest news

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本-副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

HUZHOU DAPU ADVANCED MATERIAL TECHNOLOGY CO.,LTD BE ESTABLISHED

Affected by the epidemic around the world, Positive to meet the challenge.DAPU team make a quick decision to establish a new company named HUZHOU DAPU ADVANCED MATERIAL TECHNOLOGY CO.,LTD in 2020...

Honor Certificate

What is Martensitic Stainless Steel

Martensitic stainless steel is a type of stainless steel that belongs to the martensitic class of stainless steels. These steels are known for their high strength and hardness, as well as their ability to be heat-treated to improve their mechanical properties. The martensitic class of stainless steels is characterized by a body-centered tetragonal crystal structure, which is responsible for its high strength and hardness.

Martensitic stainless steels are similar to plain carbon steels and are generally composed of iron, chromium, and carbon. They typically contain between 11.5% and 18% chromium and have a low nickel content. They can also be alloyed with other elements such as molybdenum, vanadium, and tungsten to improve their properties.

Martensitic stainless steels are known for their high strength and hardness, which makes them suitable for use in high-strength applications, such as knives, surgical instruments, and gears. They also have a good corrosion resistance in certain environments, particularly in dry, low-corrosive environments. However, they are not as corrosion resistant as Austenitic stainless steels and are more susceptible to corrosion under certain conditions.

Examples of Martensitic Stainless Steel include : 410, 420, 440A, 13C26, and 154CM etc. They are also known as 400 series stainless steel.

Martensitic stainless steels can be heat treated to achieve a wide range of mechanical properties, this make them suitable for a variety of applications that require high strength, hardness, and wear resistance.

Use of Martensitic Stainless Steel

Martensitic stainless steel is used in a variety of applications that require high strength and hardness, as well as good corrosion resistance in certain environments. Some common uses of martensitic stainless steel include:

1.Knives: Martensitic stainless steel is commonly used in the manufacture of knives, due to its high strength and hardness, which allows the blades to hold a sharp edge.

2.Surgical instruments: Martensitic stainless steel is used in the manufacture of surgical instruments, such as scalpels and scissors, due to its ability to be heat-treated to a high level of hardness, as well as its good corrosion resistance.

3.Gears: Martensitic stainless steel is used in the manufacture of gears for its high strength and hardness, which allows the gears to withstand high loads and resist wear.

4.Power generation: Martensitic stainless steel is used in power generation applications, such as turbine blades, due to its high strength and resistance to high-temperature service.

5.Mining and oil & gas: Martensitic stainless steel are used in mining and oil & gas equipment and valves, due to its strength and durability in harsh environments.

6.Automotive: Martensitic stainless steel is used in the automotive industry, particularly in exhaust systems, due to its corrosion resistance and durability.

7.Fasteners: Martensitic stainless steel is used in the production of fasteners, bolts, nuts, etc.

Martensitic stainless steel is an ideal choice for applications that require high strength, hardness, and wear resistance. However, its corrosion resistance properties are not as good as that of the Austenitic stainless steels, and thus it is not recommended for application where corrosion resistance is the prime requirement

Advantages of Martensitic Stainless Steel

Martensitic stainless steel has a number of advantages over other types of stainless steel and other materials. Some of the key advantages of martensitic stainless steel include:

1.High strength: Martensitic stainless steel has a high strength-to-weight ratio, which makes it suitable for use in high-strength applications.

2.Hardness: Martensitic stainless steel is known for its high hardness, which makes it suitable for use in applications that require wear resistance.

3.Heat-treatability: Martensitic stainless steel can be heat-treated to improve its mechanical properties, making it suitable for a wide range of applications.

4.Good corrosion resistance: Martensitic stainless steel has good corrosion resistance in certain environments, such as dry, low-corrosive environments.

5.Aesthetic appeal: Martensitic stainless steel has a sleek, modern appearance that can add a touch of elegance to any project.

Contact us now

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本-副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

English

English русский

русский