Provide you with the latest enterprise and industry news.

Guarantee High Quality With Our Expertise

-

Mr John: +86-13857275119 +86-0572-2566118

Mrs Loel: +86-13616725419 +86-0572-2566115

SUBSIDIARY:Huzhou Dapu Advanced Material Technology Co., Ltd.

Huzhou Dapu Stainless Steel Co., LTD.

About Us

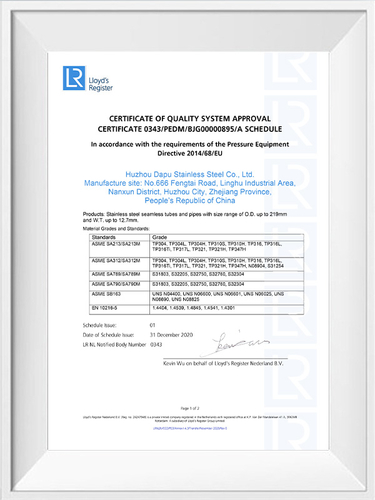

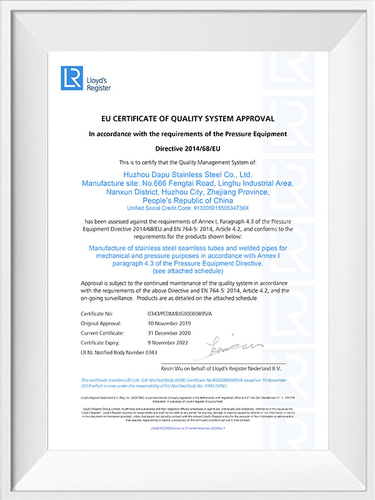

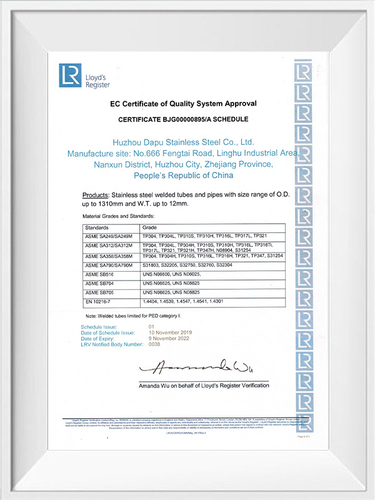

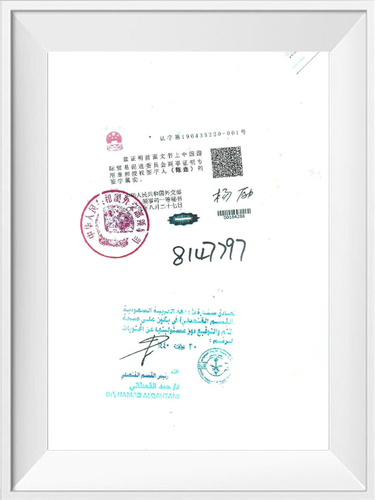

Huzhou Dapu Stainless Steel Co., LTD. is China Nickel alloy forgings Factory and OEM/ODM Nickel alloy forgings Company.As a strong corporate enterprise, the company has stainless steel (nickel-based alloy) welded pipe manufacture, stainless steel (nickel-based alloy )seamless pipe manufacture and stainless steel machine manufacture, professional production and operation of wholesale Nickel alloy forgings.focuses on more comprehensive and thoughtful to meet the requirements of the customer. Company has obtained PED, ISO and Manufacture License of Special Equipment certificates.

The company annual production capacity is 15000 tons of stainless steel welded pipe, 8000 Tons of seamless stainless steel and 5000 tons of Nickel-base alloy pipes. The company has a professional testing center,with advanced testing equipment at home and abroad: eddy current flaw detector, ultrasonic flaw detector, direct-reading spectrometer, X-raydetector, pressure unit, universal pressure test apparatus, and crystal physics and chemistry, equipment. our Nickel alloy forgings in strict line with ASTM(ASME), EN, DIN, JIS, GB and other international standard.

the latest news

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本-副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature aroun...

-

HUZHOU DAPU ADVANCED MATERIAL TECHNOLOGY CO.,LTD BE ESTABLISHED

Affected by the epidemic around the world, Positive to meet the challenge.DAPU team make a quick decision to establish a new company named HUZHOU DAPU ADVANCED MATERIAL TECHNOLOGY CO.,LTD in 2020...

Honor Certificate

Production process of nickel alloy forgings and application areas:

Contact us now

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry -副本-副本

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

-

Supply Nickel base steel GH3030 pipes be used in high temperature industry

Nickel base steel GH3030 be used in high temperature industry.(has great hot working and cold working performance )be used in the combusion chamber components of Turbine engine which temperature around 800℃.and as other high temperature parts that are required to be resistant to oxidation (less than...

English

English русский

русский